Here comes the Xhorse Dolphin XP005 (Generation 1) automotive key cutting machine maintenance manual.

This manual applies to models with serial number KM06, KM12 of Dolphin Generation I model.

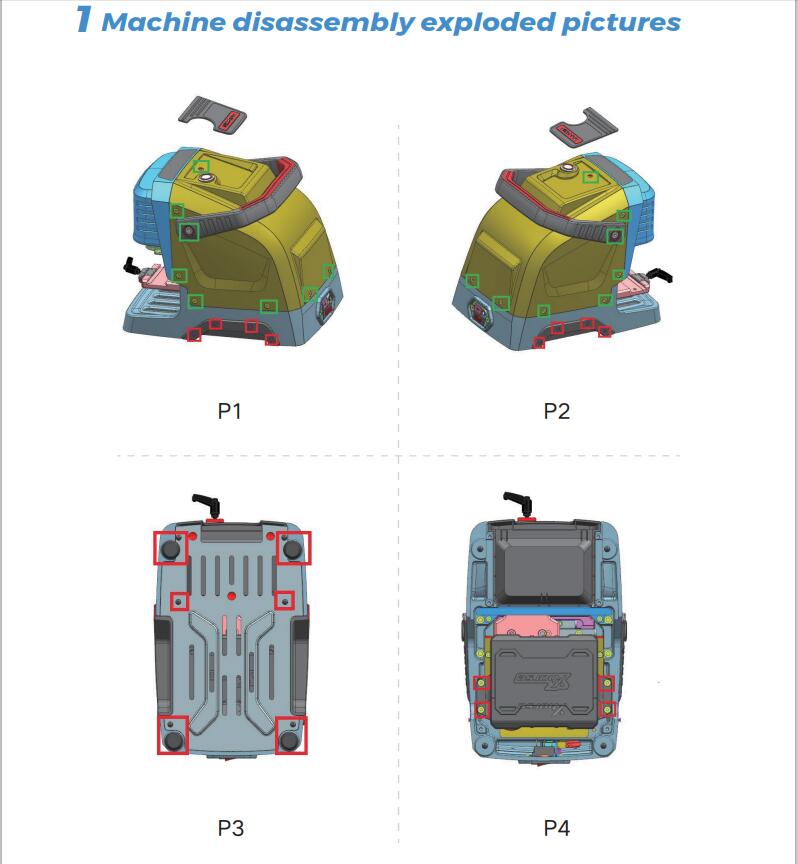

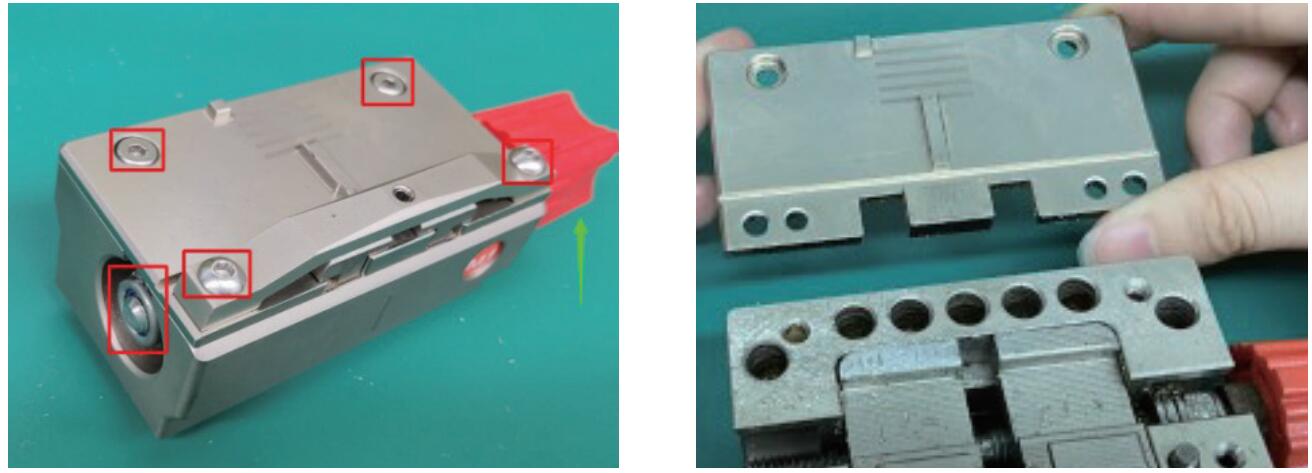

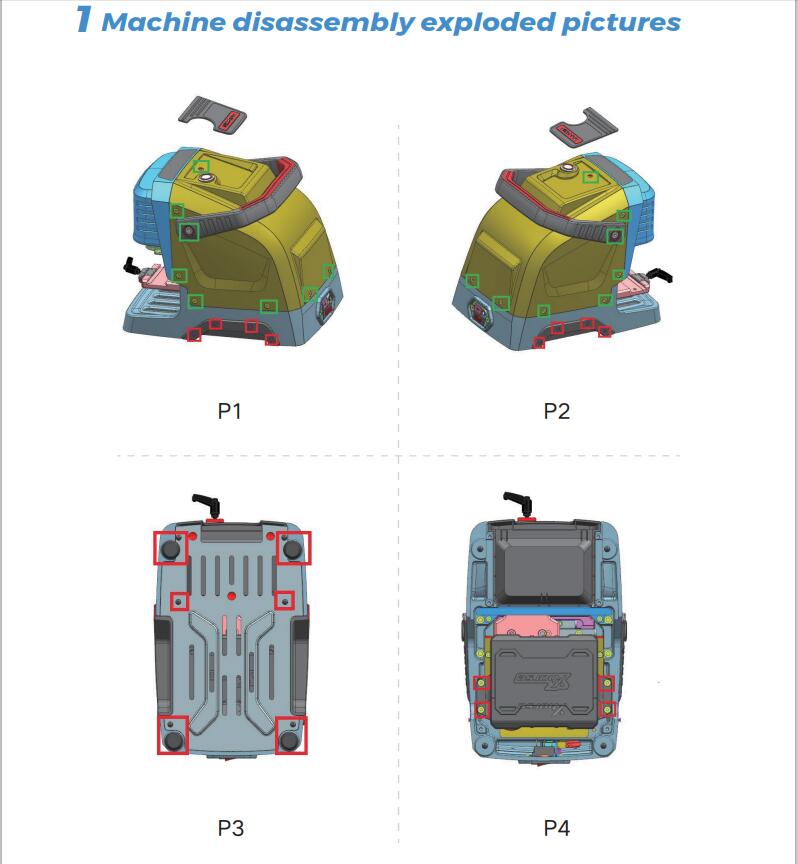

1.Machine disassembly exploded pictures

P1-P10 location

2 Method of replacing parts due to machine malfunction

2.1 Replace the battery

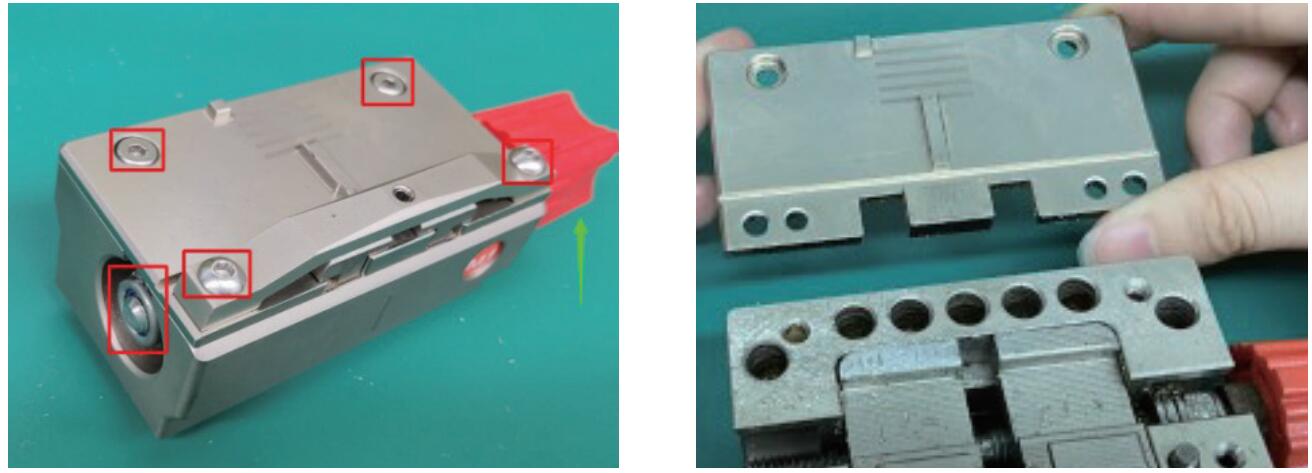

Please refer to the disassembly pictures P1, P2, P3, and P4 in Chapter 1. Unscrew the screws in the red box separately to replace the battery module with a new one, and plug in the three wirings ports of the battery accordingly.

2.2 Replace the mainboard

Reason of replacement:1. The cutter is non-conductive 2.Unable to

charge 3.Unable to power on or upgrade. 4. LED light does not light up

5. Startup error 6. Cutting error.

Please refer to the disassembly pictures P1 and P2 in Chapter 1.

Remove the screws in the green frame to remove the rear cover. Then

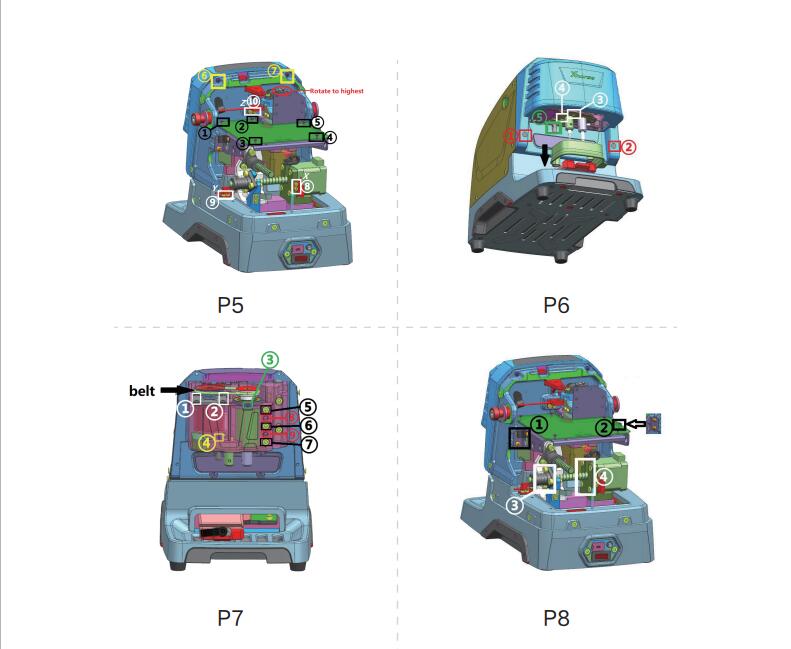

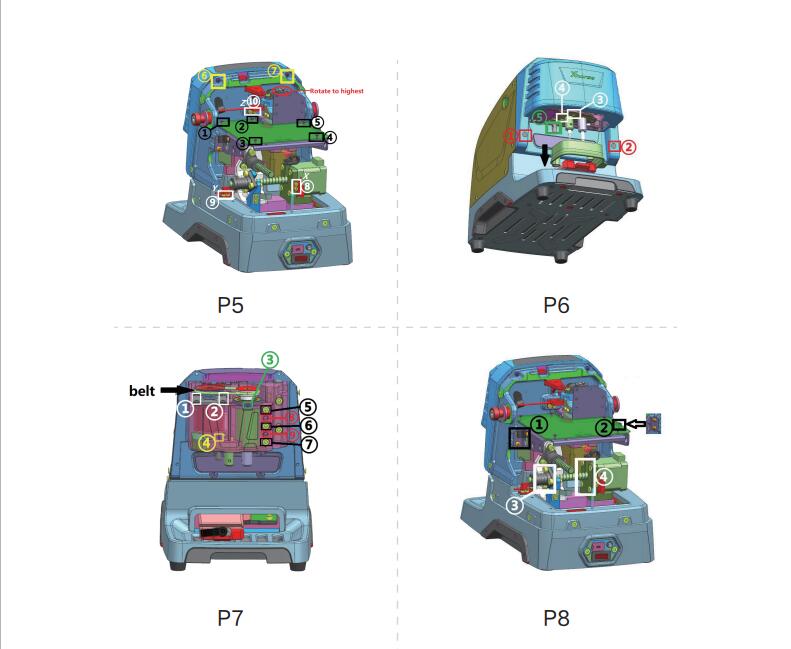

refer P5 to remove the screws at position Z of the white frame at ⑩, and

then remove the screws in the black frame at ① to ⑤ separately to

replace the mainboard with a new one. Insert the mainboard port

according to the wire harness label.

2.3 Replace the LED screen

Please refer to the disassembly pictures P1 and P2 in Chapter 1.

Remove the screws in the green frame separately to remove the rear

cover. Then refer P5 to remove the screws in the yellow frame at ⑥⑦, and

then rotate the Z-axis in the red circle clockwise to its highest

position, refer P6 to pulldown the protective cover in the direction of

the black arrow, rotate the column in the green box at ⑤to the left and

remove it, then remove the rubber plug from the red box at ①② and

unscrew the screw, and remove the front cover and screen and replace

them. Insert the mainboard port according to the wire harness label.2.4

Replace the spindle motor beltDue to long-terms use, the belt should be

replaced in a timely manner when it ages, breaks or slips(breaking the

cutter during cutting). Refer Chapter 2.3 to remove the front cover to

see the belt (shown in P7), and replace it directly.

2.5 Replace the motor

2.5.1 Replace the spindle motor

When the motor makes abnormal noise, it needs to be replaced. Refer

chapter 2.3 to remove the front cover and belt, then refer P7 to unscrew

the screws in the white frame at ①② and green frame at ③, after that,

replace it directly.

2.5.2 Replace the X-axis screw shaft motor

When the screw motor gets stuck or bent, the X-axis screw shaft motor

need to replace. Refer to the disassembly pictures P1 and P2 in Chapter

1, remove the screws in their green frame separately to remove the rear

cover, refer P8 to remove the screws in the white frame at ③④, after

that, replace it directly.To replace the x-axis rail need to refer to

chapter 2.1. Remove the battery first, then refer P9 to remove the

screws in the white frame at ①, then remove screws in the red frame at ②

and the black screwsat③④, after that, replace it directly.

2.5.3 Replace the Y-axis screw shaft motor

When the screw motor gets stuck or bent, the Y-axisscrew shaft motor

need to replace. Refer chapter 2.2 to remove the mainboard first, then

refer P8 to remove thescrews in the black frame at ①② and the white

frame at③④, remove the X-axis screw shaft motor first, then refer P10 to

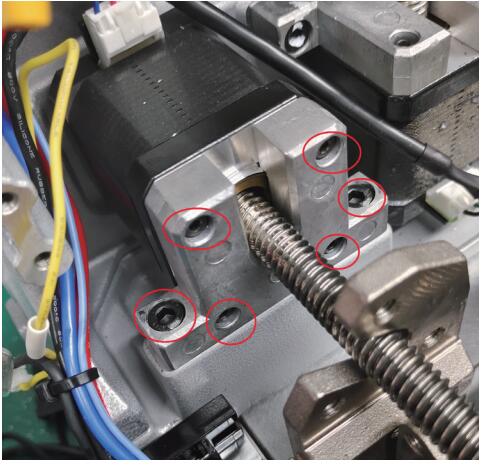

remove the screws in the black frame at ①, remove the screws in the red

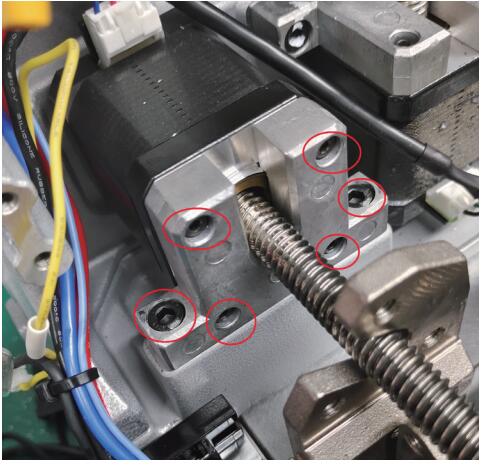

circle in the right picture , then replace the Y-axis screw shaft motor

directly.

2.5.4 Replace the Z-axis screw shaft motor

When the screw motor gets stuck or bent, the Z-axis screw shaft motor

needs to replace. Refer to the chapter2.2 to remove the mainboard

first, refer P8 to remove thescrews in the black frame at ①②, then refer

P10 to remove the screw in the white frame at②③, remove thescrews in

the red circle in the right picture, then replace the Y-axis screw shaft

motor directly.

2.6 Replace the sensor

2.6.1 Replace the X-axis sensor

When the sensor is defective or damaged, it needs to be replaced.

Please refer P1 and P2 to remove the screws in the green frame and

remove the rear cover, then refer P5 to remove the screws in the white

frame at ⑧, then replace it. Insert the mainboard port according to the

wire harness label.

2.6.2 Replace the Y-axis sensor

When the sensor is defective or damaged, it needs to be replaced.

Please refer P1 and P2 to remove the screws in the green frame and

remove the rear cover, then refer P5 to remove the screws in the white

frame at ⑨, then replace it. Insert the mainboard port according to the

wire harness label.

2.6.3 Replace the Z-axis sensor

When the sensor is defective or damaged, it needs to be replaced.

Please refer P1 and P2 to remove the screws in the green frame and

remove the rear cover, then refer P5 to remove the screws in the white

frame at ⑩, then replace it. Insert the mainboard port according to the

wire harness label.

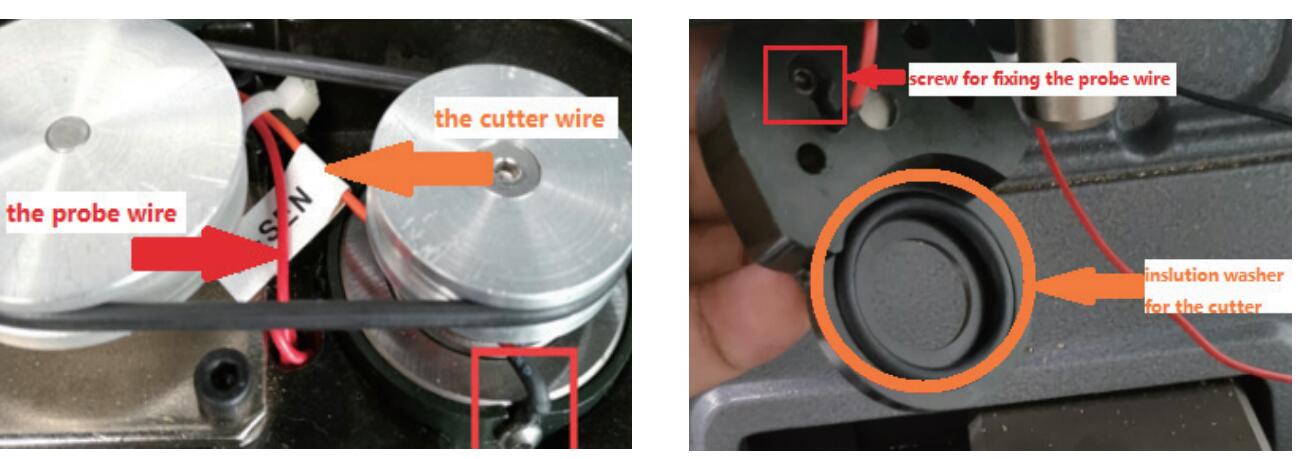

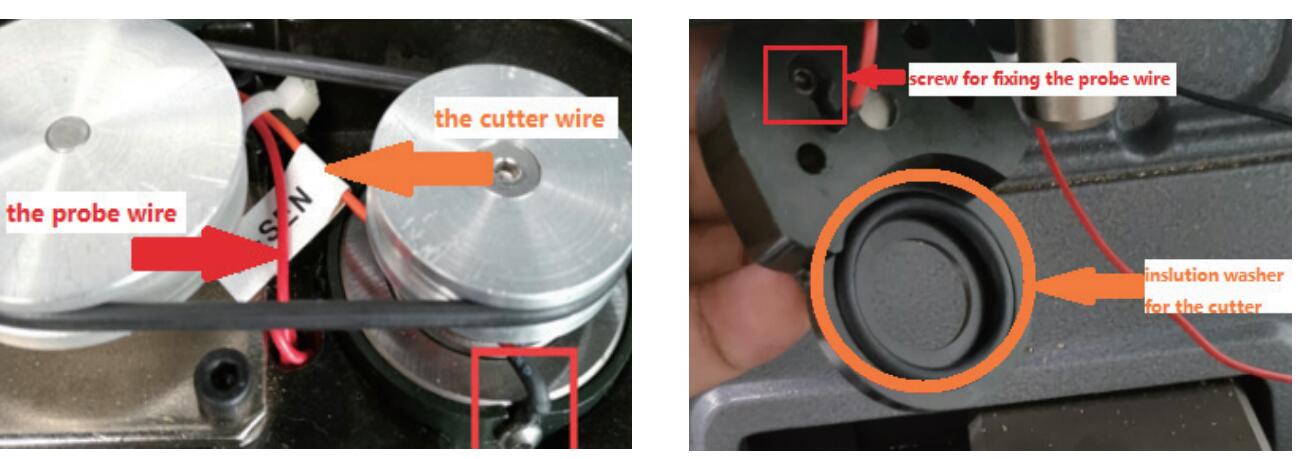

2.7 Replace or inspect the probe wires

2.7.1 The probe non-conductive

Poor contact or broken circuit caused by worn probe wires. Refer

chapter 2.3 to remove the front cover and belt, then refer P7 to remove

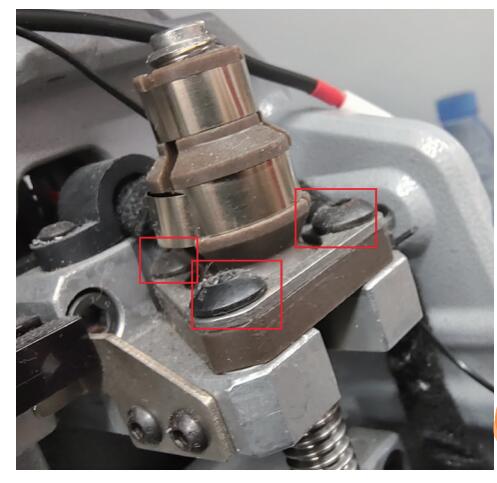

the green frame at③, refer P6 to remove the white frame at③④. As shown

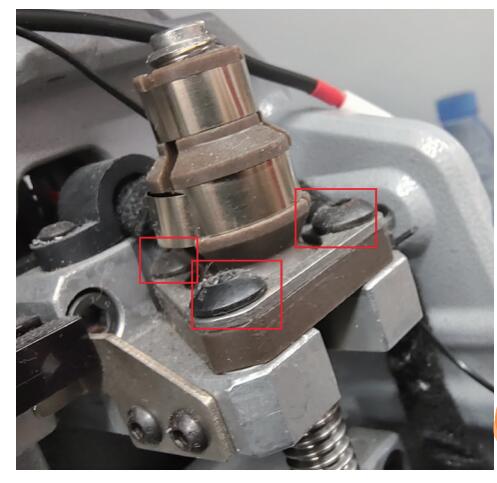

in the left picture below, gently pull the red probe wire forward while

shaking the probe base. Then in the right picture below, you can see the

screw which fixed probe in the red frame, unscrew it to replace the

probe and cutting wires. Insert the mainboard port according to the wire

harness label.

2.7.2 The probe remains conductive

Refer to chapter 2.7.1, check if the probe wire is broken, and if

there are metal debris near the fixingscrews or at the lamp panel (don’t

blow with an air gun).

2.8 Replace or inspect the cutter wires

2.8.1 The cutter non-conductive

Poor contact or broken circuit caused by worn probe wires, refer

chapter 2.7.1 to replace the probe and cutting wires. Insert the

mainboard port according to the wire harness label.

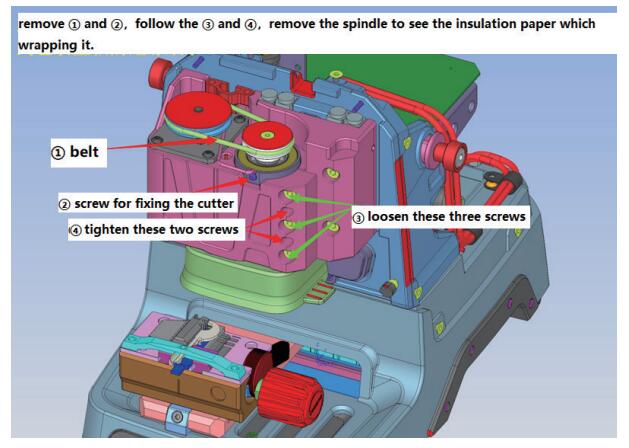

2.8.2 The cutter remains conductive

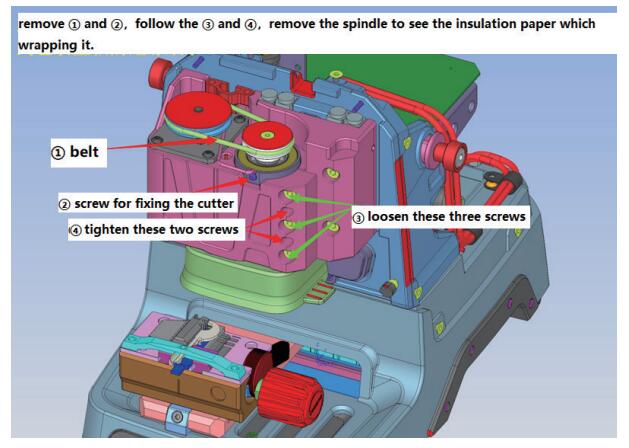

Refer to chapter 2.7.1, check if the cutter wire isbroken, and if

there are metal debris near the fixing screws or at the lamp panel

(don’t blow with an air gun).If none of the above situations exist, the

cutter remains conductive, refer P7 to loosen the screws in the black

frame at⑤⑥⑦, and tighten the screws in the red frame at⑧⑨, use your

fingers to push the cutter hole upwards slowly, then observe if the

white insulation paper is broken or if there are metal debris inside the

cutting shaft (don’t blow with an air gun), refer to the picture on the

right. when reinstalling the screws, it is necessary to refer P7 to

loosen the screws in the red frame at⑧⑨ first.

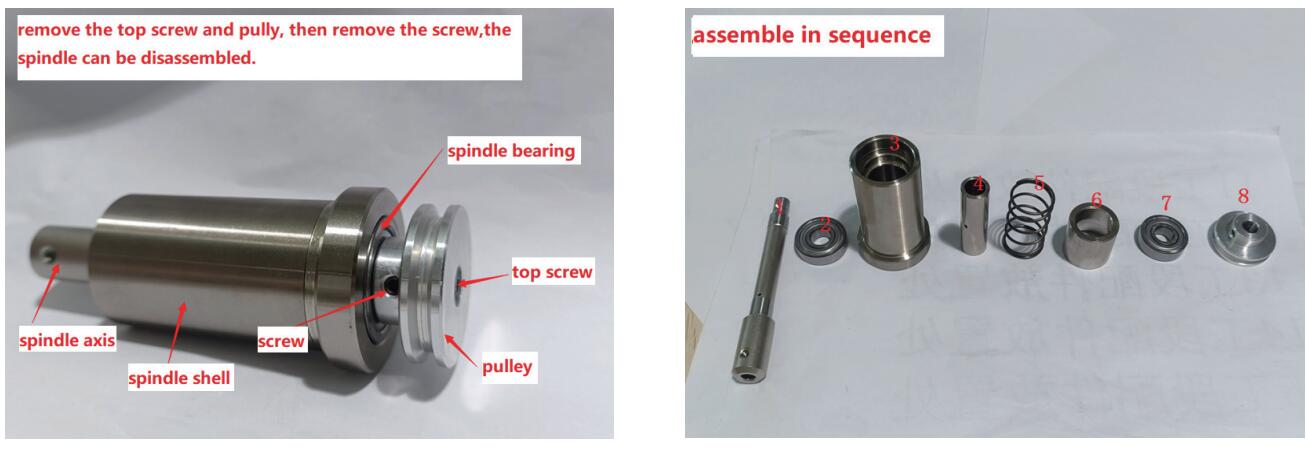

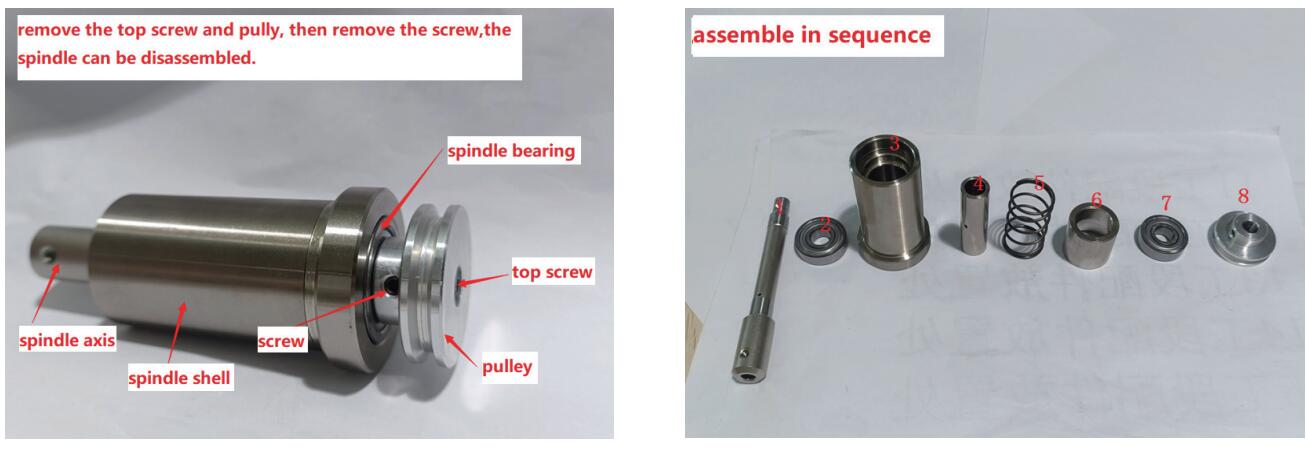

2.9 Replace the probe shaft or the cutter shaft

When the top thread of the probe and the cutter is slippery and

cannot be removed, it is necessary to replace the probe shaft or the

cutter shaft. To replace the probe shaft needs to refer chapter 2.7.1

and replace the probe base. Replace the cutter shaft needs to refer

chapter 2.8 and remove the cutter shaft, then refer chapter 2.10 to

disassemble it.

2.10 Main shaft abnormal noise maintenance

reason for abnormal noise: metal debris present, belt wear and large

gap in the shaft hole for the cutter. Refer chapter 2.3 to remove the

front cover, clean the metal debris, replace the belt, or refer P7 to

loosen the screws in the red frame at⑧⑨, and tighten the screws in the

black frame at⑤⑥⑦.The disassembly and assembly of the spindle structure

are as follows:

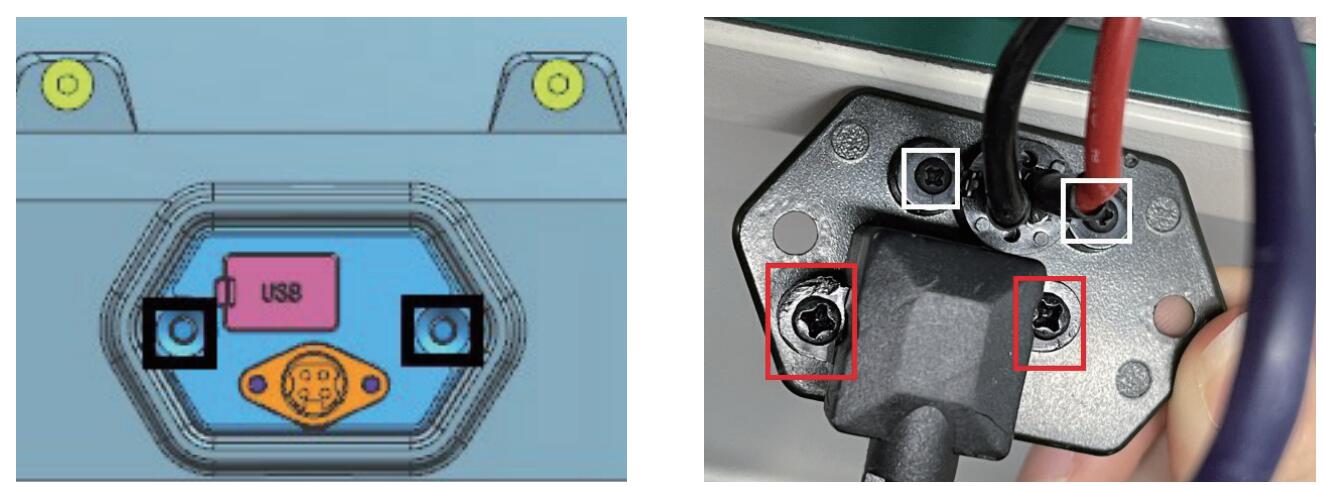

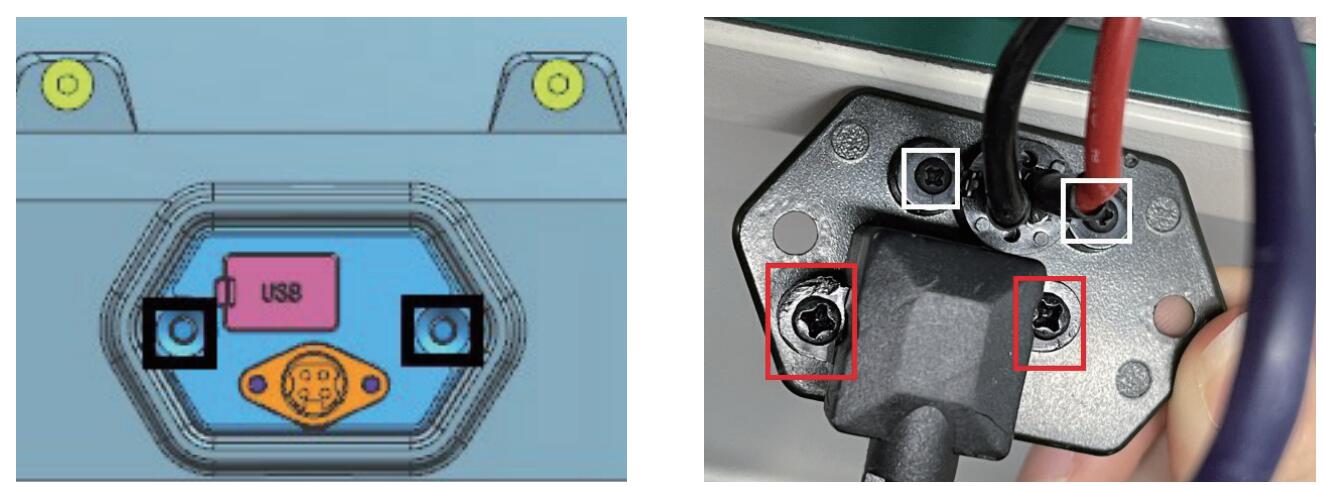

2.11 Replace the key switch and USB port

Replace the key switch should refer to the disassembly pictures P1

and P2 in Chapter 1. Remove the screws inthe green frame to remove the

rear cover. Unscrew the nut indicated by the arrow to replace it. Then

insert the mainboard port according to the wire harness label.

Replace the USB port should refer the picture below, remove the screws

in the black frame, then remove the screws in the red frame. After

replacement, insert the mainboard port according to the wire harness

label.

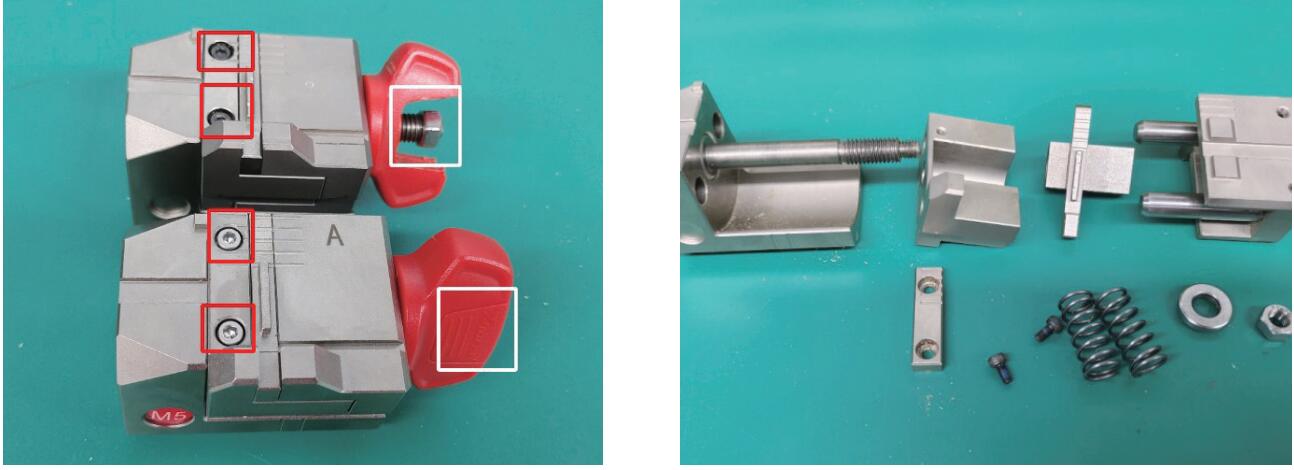

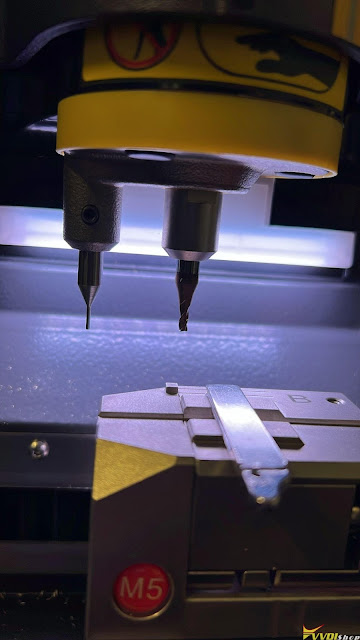

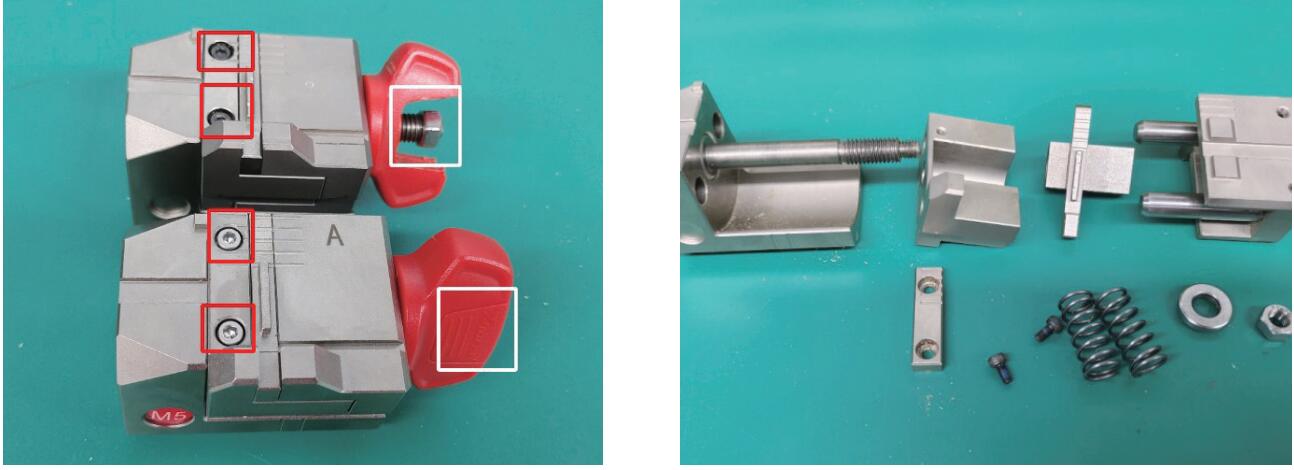

2.12 Replace clamp parts

M1 clamp: Remove the screws and nut in the red frame on the left

picture, push the knob up, then you can replace the clamp surface.

M2 clamp: Rotate the knob outward on the left picture, then it can be

disassembled. Replace the corresponding parts according to the picture

on the right.

M5 clamp:Remove

the nut in the white frame and remove the screws in the red frame on

the picture below, rotate the knob outward on the left picture, then it

can be disassembled. Replace the corresponding parts according to the

picture on the right.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)